Five (5) Stages of a Bearings Life

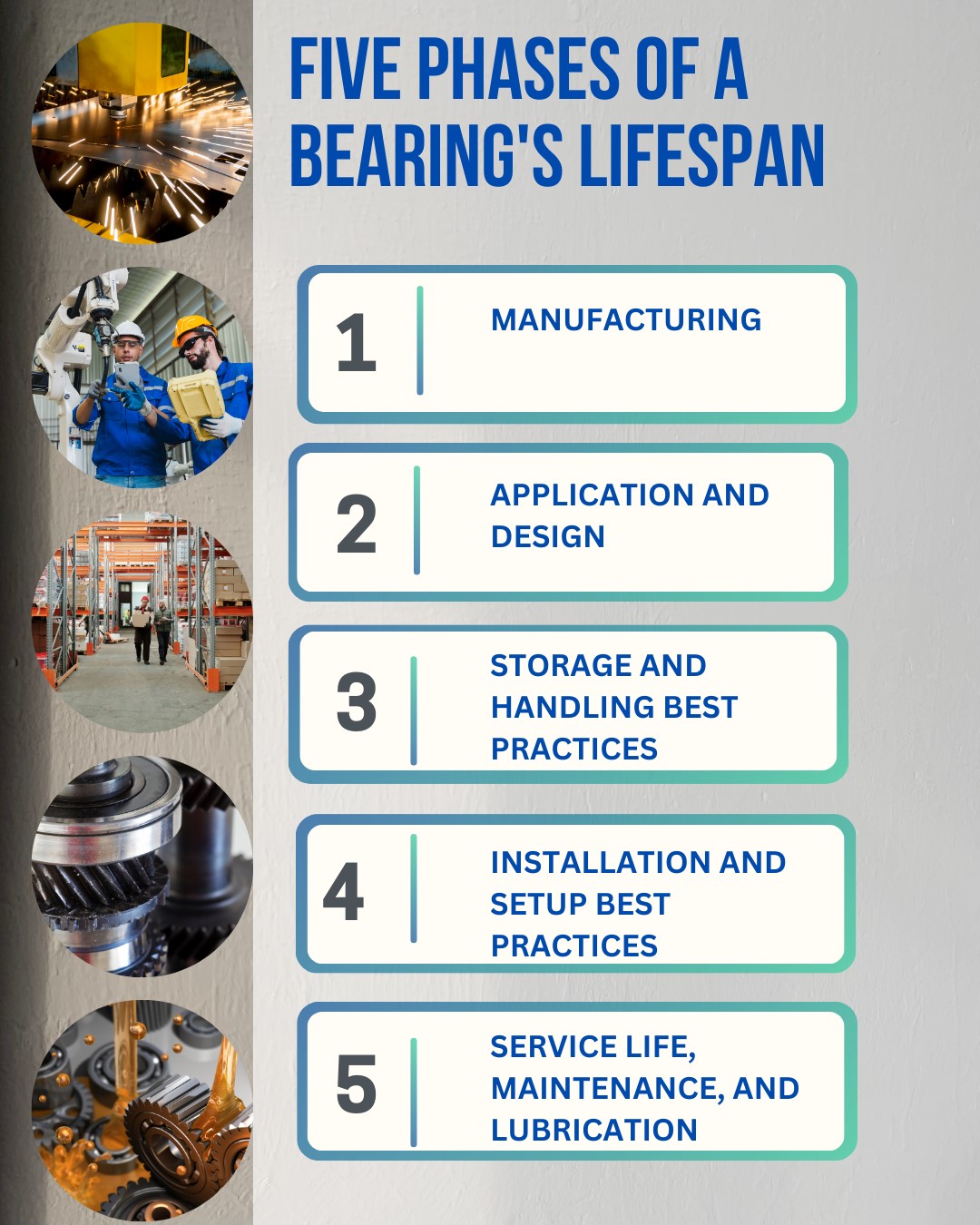

Five Phases of a Bearing's Lifespan

Apr 09, 2025

Boca Bearings

Bearings represent a fundamental element in a vast array of machines, systems, and assets, serving as essential components that facilitate smooth and efficient movement by minimizing friction between moving parts. To ensure their optimal performance and extended lifespan, it is vital to comprehend the lifecycle of a bearing, which can be categorized into a framework known as the Five Key Stages of a Bearing's Life:

1.Manufacturing

2.Application and Design

3.Storage and Handling Best Practices

4.Installation and Setup Best Practices

5.Service Life, Maintenance, and Lubrication

Stage 1: Bearing Manufacturing

The lifecycle of a bearing commences with its manufacturing process, which encompasses a series of intricate steps designed to guarantee precision and durability. Bearings can be classified broadly into two categories: mass-produced bearings and custom-designed bearings tailored for specific applications.

Material Selection

A critical initial step in the manufacturing process involves selecting high-quality materials. Reputable Original Equipment Manufacturers (OEMs) are committed to producing precision bearings with minimal contaminants. Bearings are primarily constructed from steel alloys, ceramics, or polymers, with the choice of material contingent on the specific application and performance requirements. The selected materials must exhibit key characteristics such as hardness, wear resistance, and fatigue strength.

Forging and Shaping

Upon material selection, the raw material undergoes forging and shaping to achieve the desired dimensions. For steel bearings, this usually requires heating the material followed by applying pressure to mold it into the preliminary shape of the bearing.

Machining

Following the forging process, the blanks are refined through machining operations, including turning, milling, and grinding. These procedures enhance the bearing’s dimensions and surface finish to adhere to stringent specifications. All elements, including the inner and outer races, rolling elements, and cages, are meticulously machined to tight tolerances, ensuring superior operational smoothness.

Heat Treatment

Heat treatment plays a pivotal role in improving the mechanical properties of the bearing's housing, cage, and other components. This process entails heating the parts to a specific temperature and subsequently subjecting them to rapid cooling to enhance hardness, strength, and wear resistance, which are essential for demanding applications.

Assembly

The culmination of the manufacturing process is the assembly stage, where the inner and outer races, rolling elements, and cage are assembled into a complete bearing. This process necessitates meticulous attention to detail, ensuring proper alignment and clearance. After assembly, rigorous inspections are conducted to guarantee quality and performance.

Stage 2: Bearing Application & Design

Following manufacturing, the next crucial phase involves the application and design of the bearing. This stage is instrumental in selecting and customizing the bearing for its intended use, which is often dictated by the end user.

Application Analysis

A thorough understanding of the application and specific requirements is essential for selecting an appropriate bearing. Considerations include load capacity, speed, operating environment, and desired lifespan. For example, bearings employed in high-speed applications, such as electric motors, are distinctly different from those used in heavy machinery.

Bearing Types

Different types of bearings are suited for specific applications. Common categories include:

Ball Bearings: Well-suited for high-speed applications with low to moderate loads.

Roller Bearings: More effective in accommodating heavy loads while functioning at lower speeds.

Customization

There are instances when standard bearings may not suffice for particular application requirements. In such scenarios, custom bearings can be engineered with specialized features like unique coatings, seals, or lubrication systems to enhance performance in challenging environments.

Simulation and Testing

Prior to finalizing the bearing design, simulation tools and testing methodologies are employed to validate performance metrics. Computer-aided design (CAD) software enables engineers to model various operating conditions, optimizing the design. Prototypes undergo real-world testing to confirm they align with performance criteria.

Stage 3: Bearing Storage & Handling Best Practices

Proper storage and handling practices are paramount to upholding the quality and performance of bearings prior to installation, as this stage is often where defects can occur.

Storage Conditions

Bearings should be stored in a clean, dry, and temperature-controlled environment. Excessive humidity may trigger corrosion, while extreme temperatures can alter dimensions. Ideally, bearings should remain in their original, unopened packaging until use and stored in vibration-free cabinets to mitigate the risk of false brinelling and flat spotting.

Handling Precautions

To prevent potential damage, careful handling of bearings is essential. It is advisable to handle them with clean gloves to avoid contamination from oils, dirt, or moisture, and to prevent impacts that could cause dents or deformations, compromising performance.

Inventory Management

Effective inventory management practices, such as implementing a first-in, first-out (FIFO) system, ensure that bearings are utilized in a timely manner, thus preventing degradation of quality due to prolonged storage.

Inspection Before Use

Before installation, each bearing must be inspected for any signs of damage or contamination, including corrosion or dents. Bearings exhibiting such issues should be deemed unsuitable for use.

Stage 4: Bearing Installation & Setup Best Practices

The installation and setup stage is critical for ensuring that a bearing functions correctly, thereby maximizing its lifespan.

Preparation

Prior to installation, a thorough inspection of all components and tools for cleanliness and contaminants is essential. The mounting surfaces should be scrutinized and cleansed to eliminate debris or burrs that could impact alignment.

Installation Methods

Depending on the bearing type and application, various installation techniques may be employed, including press fitting, shrink fitting, or using specialized tools like bearing heaters. Each method requires ensuring that bearings are properly fitted to shafts without force, with appropriate attention to alignment and balancing, adhering to manufacturer guidelines.

Alignment and Clearances

Achieving proper alignment and maintaining precise clearances are vital for optimal bearing performance. Misalignment can result in uneven load distribution and premature wear. Precision instruments should be used to verify correct alignment with the shaft and housing.

Lubrication

Correct lubrication upon installation is crucial for minimizing friction and wear. The recommended lubricant must be applied in the correct quantity, as both over-lubrication and under-lubrication can result in performance issues. Additionally, it is imperative to choose a lubrication approach that aligns with the bearing type and application.

Stage 5: Bearing Service Life, Maintenance, & Lubrication

The final stage in a bearing's lifecycle focuses on service life, maintenance, and lubrication practices.

Regular Inspections

Routine inspections are essential for monitoring the bearing's condition and detecting any signs of wear or damage. Utilizing visual inspections, ultrasound assessments, vibration analyses, and temperature monitoring can provide critical insights into the bearing's health.

Maintenance Practices

Adopting effective maintenance strategies can significantly prolong a bearing’s service life. The recommended OEM practices serve as foundational guidelines but should be adjusted according to specific operating conditions and environments, encompassing regular cleanings, re-lubrication, and necessary adjustments.

Lubrication Management

Effective management of lubrication is crucial for sustaining bearing longevity. Steps must be taken to ensure that bearings are adequately lubricated based on operational conditions—with grease bearings requiring periodic re-greasing and oil-lubricated bearings necessitating oil changes or top-ups. Lubricants should be stored properly to prevent contamination.

Ultrasound for Precision Condition-Based Lubrication

Utilizing ultrasound technology for re-lubrication has emerged as a sophisticated method within the industry. Through monitoring the high-frequency sounds emitted by bearings, which fluctuate according to their lubrication status, maintenance teams can accurately determine lubrication needs. This proactive approach minimizes the risks of under-lubrication or over-lubrication by responding to changes in friction levels captured by ultrasound readings.

Addressing Issues

Prompt identification and resolution of inspection-detected issues—such as misalignment, contamination, insufficient lubrication, or overloading—are crucial to preventing severe failures and costly downtimes. Repetitive issues warrant a comprehensive Root Cause Analysis (RCA) to determine their origins and implement preventative measures.

End of Life

Ultimately, despite diligent maintenance, bearings will culminate their service life. Recognizing the signs for replacement—including increased noise, vibration, and temperature, along with visible damage—is essential to avoiding unforeseen failures. A bearing’s designed life (L10) serves as a benchmark for expected longevity, and any bearings that significantly underperform in this regard should prompt discussions for process improvements to enhance longevity.

Conclusion

A comprehensive understanding of the five key stages in a bearing's lifecycle—from manufacturing to service life—is essential for ensuring the optimal function and maximum longevity of these vital components. Adhering to established best practices throughout the bearing lifecycle bolsters machinery reliability, mitigates downtime, and ultimately conserves costs. As such, meticulous care and attention to each stage are pivotal for sustaining the seamless operation of equipment across diverse applications, irrespective of industry or operating conditions.